Foreword

With the introduction of "Made in China 2025", the manufacturing industry has ushered in a brand new development opportunity. More companies apply manufacturing information technology extensively, such as the research and application of MES systems, digital twins, and visualization of production management, which have become a hot spot of common concern from all walks of life.

Surface Mounted Technology (SMT) refers to the abbreviation of a series of process processes that are processed on the basis of Printed Circuit Board (PCB), and is the most popular technology and process in the electronics assembly industry. SMT has been developed for more than 40 years and is now widely used in communications, computers, home appliances and other industries. And with the coverage of the 5G network, the Beidou-3 satellite navigation system was completed and opened, and the rapid development of the electronic information industry has urged the development of SMT technology in the direction of high density, high performance, high reliability and low cost.

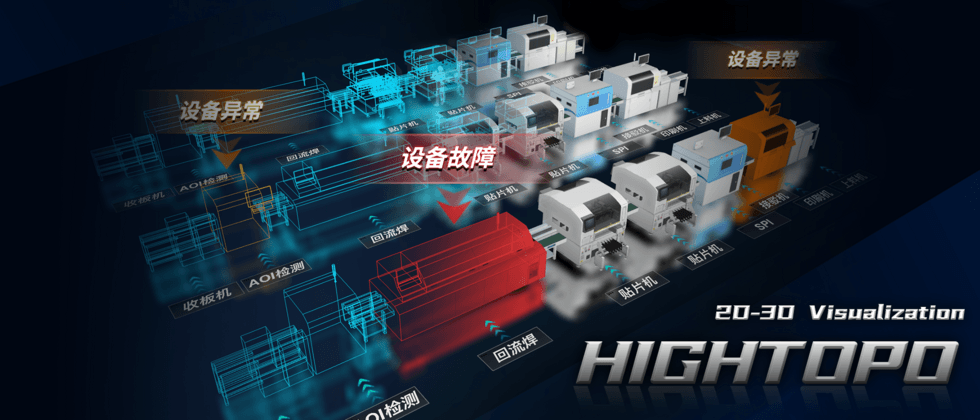

This article will take the SMT production line as an example to introduce the use of HT's rich 2D and 3D configuration to visualize digital twins and build a visual system for SMT process monitoring and management. Create an intelligent and green digital smart factory.

effect rendering

The initial scene of the screen is set to be loaded in the form of a sci-fi style chip. Click the chip to switch to the main scene. It shows the application of HT from the micro to the macro world.

The presentation of the three-dimensional model of the SMT plant is the first step to realize the control of production line equipment, personnel, and on-site.

HT uses the equipment pictures, equipment layout, plant layout, plant CAD and other information collected on the SMT production line site to perform isometric modeling of the production line and restore it to a three-dimensional scene.

Through the three-dimensional scene, users can intuitively see the material area in the plant and each production line equipment, such as: printing presses, SPI inspection machines, placement machines, reflow soldering, AOI inspection equipment, etc. The locations of AGV cars, cameras, firefighting equipment, air conditioners, TVs, etc., as well as the real-time data and operating status of the corresponding equipment, can be visually displayed in the three-dimensional scene, and the overall linkage of the scene is realized through the Internet of Things technology.

system analysis

Manufacturing data visualization

According to the needs of industry operations and government and enterprise decision-making, the main data of the overall production line can be displayed through the multi-dimensional data panel. Based on the construction and operation results of user data, the boring and scattered data can be graphically and visualized. Display the overall equipment effectiveness (OEE), time utilization, performance utilization, output completion, through rate, equipment utilization rate, defective rate, IoT connection rate, etc. of each line body. Intuitively monitor the status of production line equipment, production quality, inventory information, etc., to improve the efficiency of factory operation decision-making.

On this basis, the graphical data panel is developed through HT to realize the dynamic data loading effect, and compare each chart data more intuitively. The visual effect felt by the user is compared with the static chart data, which can be described as a success , Go further!

equipment information visualization

Realize the visualization of key equipment business data in the 3D scene through the docking data interface, display the key equipment status on the page, and use different color device values and icons to represent different equipment status. And add the intelligent early warning analysis function, once the device data exceeds the established threshold and the historical data is analyzed and judged, the device will be flashed in red in the 3D scene to show the alarm state. The routine manual inspection is converted to the intelligent inspection, so as to know the health status of the equipment in time and reduce the labor cost of factory operation.

indoor positioning

Realize the indoor positioning function of the scene through the emerging Internet of Things 5G+, Bluetooth 5.0 and other technologies. With the help of smart base stations, wearable devices, and front-end communication technology, the positioning coordinate data is transmitted to the front end to realize the positioning function of personnel and AGV cars. In addition, it can also realize the actual point-to-point animation of personnel and cars according to the coordinates, which is convenient for users to visualize In the scene, the real-time position of the field operator and the AGV car is observed in time. And HT also supports the drawing of historical running trajectories. Drawing the historical trajectory can also help managers analyze the rationality of the production line layout and make corresponding adjustments in time.

video access

In addition to the above-mentioned users who manage and control on-site equipment through 3D scenes, the video surveillance system is also of more concern to users. At present, common video surveillance is integrated in its own system, and the cameras are distinguished by text naming. This method is likely to cause a series of problems: video dispersion, isolation, incomplete viewing angle, and unclear hardware location. Therefore, how to manage cameras and control video dynamics more intuitively and clearly has become an important topic for enhancing the value of video applications. HT uses the actual position of the on-site camera as a reference, and places the model at the corresponding position in the three-dimensional scene to realize the scene restoration. Through the three-dimensional scene, the user can clearly see the location of the camera in the factory. It is also possible to use emerging video fusion technology to seamlessly embed video into the scene to truly restore the real scene of the scene.

realizes value

The HT 3D visualization technology adopts the B/S architecture. After the above-mentioned equipment visualization process is processed by the lightweight model, users no longer need to spend high prices to purchase high-performance graphics workstations to support the 3D visualization system. Users can access the 3D visualization system anytime and anywhere through a PC, PAD or smart phone as long as they open a browser to realize remote monitoring and control. Through the combination of the B/S architecture and the lightweight model, the HT 3D visualization technology firstly reduces the pressure of users on purchasing high-performance hardware to a certain extent, and secondly breaks the limitations of the previous management scenarios where users manage in the monitoring room.

summary

Hightopo has shared many three-dimensional visualization systems in the power, data center and other industries. In addition, manufacturing, photovoltaic energy, and electronic equipment production lines in the industry can also be used as objects to achieve them through three-dimensional visualization technology. management. HT visually empowers the intelligent manufacturing and digital transformation of the industry, enables traceable management of industrial operation and maintenance, enables monitoring and management of equipment operation, and enables all things to be "interconnected".

For more industry application examples, please refer to the case link of Software official website: 160bce2fcbe0d3 https://www.hightopo.com/demos/index.html

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。