Foreword

At about 16:00 on September 26, 1959, a black oil stream ejected from an oil well named "Songji Mitsui" near a small town called Datong on the Songnen Plain, marking a world-class super large continental sandstone oil field. Birth. After the Daqing Oilfield started production, our country got rid of China's "poor oil" hat. Because of the Daqing Oilfield, China’s newly-added proven oil reserves reached 2 billion tons in 1961. In August 2021, PetroChina Daqing Oilfield once again discovered 1.268 billion tons of shale oil fields in Daqing, and my country's oil reserves increased to 31.4 billion tons.

As early as 2020, Daqing Oilfield proposed to promote the "three-step" strategy of digital oilfield-smart oilfield-smart oilfield, taking data as a key production factor, and building a whole-process system of data collection, transmission, analysis, and decision-making, through digitization and exploration The in-depth integration of development business drives technological change, production change, and management change, and drives high-quality development of oil fields.

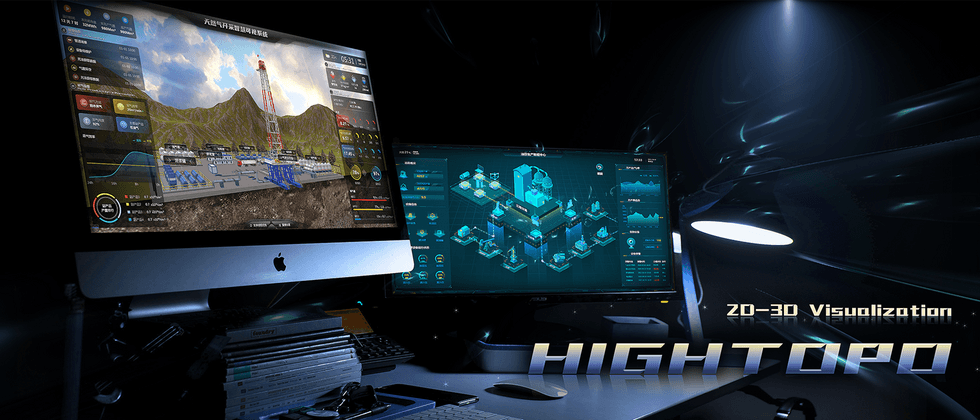

Effect display

Tupu Software’s online smart oilfield uses a 2.5D lightweight design. Based on the Sichuan map, it shows the distribution of oil fields in the entire province. Use Hightopo's independent research and development core product HT for Web to realize interactive two-dimensional Web scenes. Understand the entire process of petroleum exploration-petroleum extraction-oil and gas gathering and transportation-downhole operations-petrochemical industry through 2D configuration. Using RFID, sensors, GPS, cameras and other equipment, combined with 5G and AI recognition technologies, realize the intelligent identification, perception, positioning, tracking, monitoring and management of oilfield facilities.

Tupu Software focuses on the industrial field and provides a complete assembly line operation tool chain, from 2D design, 3D design to interaction, motion effects, there is a one-stop development tool, designers and programmers can realize collaborative work development, quickly landing 2D, 3D visualization Results.

Oil and gas exploration

Use a variety of exploration technologies and facilities to collect data, find traps for oil and gas storage, and ascertain the area of oil and gas fields, oil and gas layers, and production capacity. Many oil fields or exploration areas are in inaccessible areas, and it is difficult for decision-making and management to perceptually understand the real conditions of the natural environment, geology, engineering, construction, and transportation of the oil field. If the data is connected to the large visual screen of Tupu, the manager can grasp the important data of the exploration process of the oil field and the development of the oil reservoir in real time.

Petroleum exploration can be divided into two stages: investigation and exploration. The main task of the investigation stage is to investigate the conditions of the existence of oil and gas reservoirs through ground geological survey or geophysical survey or geochemical exploration. After understanding the geological situation, the reflected wave seismic exploration method can be used for detailed investigation. In the detailed investigation to determine the possible oil-bearing structure, the method of drilling wells is used to confirm the existence of oil and gas layers by taking cores and testing oil and gas layers. After drilling, it is necessary to study the geological characteristics of the oil and gas reservoir (oil-bearing layer change law, pressure system and production dynamics, oil, gas, and water conditions) in detail, calculate the accurate reserves, and obtain all the necessary data for oil reservoir development.

When we use geological, geophysical, geochemical, and drilling methods to obtain the original data of oil and gas fields, the data is fused, processed, and converted to form visual charts of daily production trends, oil field resource distribution, and oil field production rankings. Show the overall complexity of the oilfield to managers objectively, allowing them to make reasonable plans in advance for the project in each stage of exploration, construction, and construction, and make many deployment plans and development plans better in site selection, line selection, and operation. Reasonable, reduce risks, and improve economic benefits.

Environmental protection

With the implementation of the national "dual carbon" policy, low carbon emissions and environmental protection are closely related to corporate interests. Petroleum and natural gas exploitation is a heavily polluting industry. During the exploitation process, atmospheric pollutants mainly include exhaust gas from natural gas purification plants, fugitive hydrocarbon waste gas from oil and gas processing and gathering and transportation systems. The main pollutants are SO2 and VOCs.

In the process of petroleum production, storage, transportation, refining, processing, and use, due to accidents, abnormal operations, and maintenance, there will be spills and discharges of petroleum hydrocarbons, causing pollution of the atmospheric environment, soil, and groundwater. Such as the greenhouse effect, the destruction of the ozone layer, the soil structure, etc., forming an environment where no grass grows. Through the monitoring of the large visual screen of Tupu, problems can be found in time. Use in-situ bioremediation technology, hetero-situ bioremediation technology, phytoremediation technology, biological treatment method, or filter equipment to purify air and water.

Oilfield water treatment filter

It is mainly suitable for treating all kinds of wastewater whose floc proportion is close to water after reaction. According to the water quality characteristics of oily wastewater and reinjection water quality requirements, the main removal factors are suspended solids, petroleum substances, sulfides and iron, and the diameter of particles in the reinjected water after treatment is guaranteed to be <1.0 μm. Filtered water can be reused to protect our country's fresh water resources.

The clean water tank can be used to store clean water and connect with the fire fighting system. There is no need to set up another fire fighting pool, which reduces the floor space and protects the environment.

With the help of HT visualization technology, basic information other than oilfield information can be obtained, such as cadastral, meteorological, hydrological, natural earthquake, vegetation and other minerals and other information related to space systems, which is helpful for management, construction, and environmental protection in the oilfield area. And prevention of natural disasters.

oil extraction

When the exploration of the oil reservoir is completed and the type and reserves of the oil reservoir are determined, drilling operations and cementing will be carried out. When the oil and gas reservoirs are drilled through perforation, the construction of surface facilities is completed, and the well completion device is installed, it indicates that the basic conditions for oil exploitation have been established.

Oil well development

Use derricks, operating platforms, diesel engines, drilling rigs, drilling tools, mud pumps, generators and testing equipment, fuel oil tanks, boilers, etc. to drill the formation into holes from the ground. The casing is run into the well, and cement is injected into the annular space between the wellbore and the casing. Use perforating ejection to open the casing and cement ring of the target layer to form a communication channel from the formation to the wellbore to facilitate oil and gas production operations.

The digital twin of the drilling equipment shares data information with the physical equipment, monitors the equipment power, speed change, operation status and other data, and realizes digital management. Combining the real-time acquisition of seismic data and the comprehensive analysis and comparison with historical seismic data and exploration and development data, it realizes accurate calculation of oil and gas reserves, accurate prediction of enrichment and high-yield areas, and accurate identification of geological risks.

Oil extraction method

Self-injection oil production and artificial lift oil production are two methods of oil production. Self-injection oil production is a method in which crude oil can be ejected from the wellhead by its own pressure due to the high pressure of the underground oil-bearing layer. Artificial lift oil extraction uses various types of pumps to pump crude oil out of the well. At present, my country's oil extraction is dominated by artificial lift oil extraction. Use Hightopo's independent research and development core product HT for Web to realize interactive two-dimensional Web scenes. Click on the pumping unit to drill down to the equipment details page.

According to the lifting method, it is divided into two types: gas lift oil production and deep well pump oil production. Among them, there are rod pump oil extraction, screw pump oil extraction and so on. Rod pump oil production relies on mixing the high-pressure gas injected into the well from the surface with the oil produced fluid in the wellbore. The expansion of the gas reduces the density of the mixed liquid in the wellbore and lifts the crude oil flowing into the well to the surface.

Rod pump

Pumping unit is the main ground equipment for oil extraction with rod deep well pumps. It converts electrical energy into mechanical energy, including beam pumping units and beamless pumping units. When the sucker rod is working, the power equipment transmits the high-speed rotation motion to the crank through the reduction box, which drives the crank to rotate at a low speed; the crank drives the beam to swing up and down through the connecting rod; the rope suspension hanging on the donkey's head is driven by the sucker rod The downhole deep well pump reciprocates up and down to pump oil to the surface. Oil well pump is a device that converts mechanical energy into fluid pressure energy. It is mainly composed of working cylinder (outer cylinder and bushing), plunger, swimming valve (discharge valve), and fixed valve (suction valve).

Comprehensive use of various sensing technologies, wired/wireless communication technologies, and data analysis technologies, with intelligent control as a means, around each link of the rod pumping system, such as pumping units, sucker rods, and pumps. Conditions and various operating parameters are collected, processed and excavated, parameter configuration is optimized, oil production efficiency is improved, operating costs are reduced, and safe, stable and efficient production is maintained.

Oil-gas-water three-phase separator

A "solid, liquid, and gas" three-phase separation device installed under the pump in an oil and water well in an oil field. The oil-gas-water mixture enters the pre-degassing chamber at a high speed, and a large amount of crude oil-associated gas is extracted by cyclone separation and gravity. The layer is washed and demulsified, the flow is stabilized, and the Reynolds coefficient of the incoming liquid is reduced. After coalescing and rectification, it flows into the sedimentation separation chamber for further sedimentation and separation. The degassed crude oil passes through the baffle and enters the oil chamber, and is measured by a flow meter for control. After it flows out of the separator, the water phase enters the water chamber through the pipe through the pressure balance, so as to achieve the purpose of three-phase separation of oil, gas and water. Realize crude oil dehydration, crude oil de-natural gas and natural gas de-light oil; sewage recovery, natural gas recovery and light oil recovery must also be achieved.

Visually monitoring the data of the three-phase separator through HT, combining the automation and informationization of oilfield production, and applying the Internet of Things and cloud computing technology to the oil and gas production process have become the mainstream direction of domestic digital oilfield construction.

Water injection electric booster pump

Water injection is a secondary oil recovery method. Inject water into the formation through water injection wells to drive underground crude oil to production wells and increase the oil recovery rate after one-time oil recovery.

Injection well

A well used to inject water into an oil reservoir. In the process of oilfield development, water is injected into the reservoir through a special water injection well to maintain or restore the pressure of the oil layer, so that the reservoir has a strong driving force to increase the rate of production and recovery of the reservoir. The water injection equipment is used to inject water of satisfactory quality into the oil layer from the water injection well to maintain the pressure of the oil layer. This process is called oil field water injection. Oilfield water injection is one of the important means to add energy to the formation and improve oilfield recovery in the process of oilfield development. The level of water injection well management technology determines the effectiveness of oilfield development, as well as the length of oilfield development life.

Oil and gas gathering and transportation

After the formal exploitation of oil and gas, the oil, associated natural gas and other products produced by the scattered oil wells need to be concentrated, processed by various equipment, and initially processed, and then the qualified oil and natural gas are exported to refineries and natural gas users respectively. The various spatial entities of the oilfield can be naturally organized through the HT visualization platform, which will completely break the horizontal division of various professional information platforms in the oilfield, and form an oilfield information system integrating exploration, development, engineering, and transportation.

Heating furnace

Refers to special equipment that uses flames to heat crude oil, natural gas, water and their mixtures and other media. It is the most widely used special equipment for oil fields in the oil and gas gathering and transportation system. Its function is to heat crude oil, natural gas, oil-water mixture, and oil-gas-water mixture to the temperature required by the process to meet the requirements of the oil and gas gathering and transportation technology and processing technology. From the oil production wellhead to the entire gathering and transportation system of crude oil export, heating furnaces are used in all links. The heating furnace is also a kind of high energy consumption equipment. The correct operation and use of the heating furnace is of great significance for improving thermal efficiency and reducing fuel consumption.

oil storage tank

It is a container for storing oil, the main facility of the oil depot, and the oil source interface of the oil pipeline in pipeline transportation. According to the material, it can be divided into two categories: non-metal oil cans and metal oil cans. Metal oil tanks are widely used because of their low cost, low leakage, convenient construction and easy maintenance. Spherical oil tanks have the characteristics of pressure resistance and material saving, and are mostly used in liquefied petroleum gas systems.

The visualization system can easily gather information on oilfields with dense equipment pipeline networks, tens of thousands of kilometers of long-distance oil and gas pipelines, and supporting tens of thousands of crude oil storage tanks to form digital planning, management, safety monitoring, design and drawing capabilities.

In addition to land oil resources, my country is also very rich in marine oil and gas resources. Offshore oil and gas exploration is mainly concentrated in the Bohai Sea, the Yellow Sea, the East China Sea and the northern continental shelf of the South China Sea. Offshore oil and gas gathering and transportation map software also has completed visualization solutions.

Natural gas extraction

For natural gas stored in the same layer as crude oil, it will be mined together with crude oil. For gas reservoirs where only single-phase gas exists, the extraction method is very similar to that of crude oil, but also has its own special features. China was the first country in the world to develop and utilize natural gas. The Song Dynasty began to develop and utilize natural gas on a large scale. The Ziliujing gas fields located in Zigong City, Fushun County and Rong County of Sichuan Province were the largest natural gas fields in the world at that time.

Hightopo is a smart visual system for natural gas extraction. The opening animation shows the three stages of gas field construction: pre-drilling engineering, drilling engineering and well completion operations. Including: fixed well position, road survey, foundation construction, installation of derrick, moving, installation of equipment, primary drilling, secondary drilling, drilling, tripping, bit change, drilling, completion, electrical testing, casing running , Cementing operations, etc.

Using Hightopo's self-developed core product HT for Web, an interactive 3D Web scene can be realized, which can be zoomed, translated, and rotated to display the facility and equipment information of the natural gas field. The 2D panel accesses real-time data to display information such as natural gas production, equipment failure information, gas production purity, gas production efficiency, and natural gas inventory. The physical wireframe switch at the bottom of the interface can view the wireframe status of the gas field.

Due to the low density of natural gas, 0.75-0.8 kg/m3; low viscosity, low flow resistance in formations and pipelines; but large expansion coefficient and large elastic energy. Therefore, the self-injection method is generally used in natural gas extraction, which is basically the same as the self-injection oil production method.

Drainage gas

Associated gas usually contains impurities, and the heavier gas can be separated by flash separation. In order to improve the recovery rate of associated gas light hydrocarbons, a medium-pressure shallow cold cold oil absorption process can be used. It has the characteristics of high recovery rate, good economic efficiency, wide range of process adaptability, and large operation flexibility.

In fact, the key to improving gas recovery is flood control. Because the elastic energy of the water body will drive water into the gas reservoir along the high permeability zone, the hydrophilicity of the rock itself and the effect of capillary pressure, the intrusion of water will seal the gas that is not discharged in the fractures or voids, and the specific gravity is as high as the rock pore volume. 30%~50%, greatly reducing the gas recovery rate.

After the gas well produces water, the percolation resistance of the gas flow into the bottom of the well will increase, and the total upward energy consumption will increase. The gas production rate of the gas reservoir will decrease, the self-blowing capacity of the gas well will be weakened, and the production of a single well will decline rapidly until production is stopped. Judging the degree of water seepage through the data changes of gas production efficiency, gas production purity, water saturation, mud content, and permeability. Through methods such as drainage and gas recovery, chemical plugging, etc., it can solve the problem of excessive fluid accumulation or water production in the gas well bore and near the bottom of the well, so that the gas well can resume normal production.

Statistics

The water seepage situation in the gas well can be judged by the ratio of electricity consumption and gas production in the current month, and remedial measures can be taken in time.

Alarm information

Through the large visual screen of Tupu, the equipment failure monitoring can be realized in the central control room, and the engineering staff can be notified for maintenance in time.

by-product output ranking

It can analyze the output of stable gas condensate (SGC) and other by-products, and scientifically allocate resources.

Downhole operation

In the long-term production process, oil and water wells are constantly corroded by underground oil, gas, and water, and gradually age, and various types of failures occur, causing oil and water wells to fail to produce normally or even stop production. Therefore, it is necessary to carry out downhole operations on the oil and water wells with problems and failures to restore the normal production of the oil and water wells. Downhole operation is a technical means to ensure the normal production of oil and water wells in the process of oilfield exploration and development. Mainly include oil and water well maintenance, oil and water well overhaul, oil reservoir reconstruction and oil testing.

Underground operations are dangerous, and through visual inspections and robot overhauls, workers’ health will be guaranteed.

Petroleum and natural gas chemical industry

Petrochemical products are obtained by further chemical processing from the feedstock oil provided by the refining process. The first step in the production of petrochemical products is to crack raw oil and gas (such as propane, gasoline, diesel, etc.) to produce basic chemical raw materials represented by ethylene, propylene, butadiene, benzene, toluene, and xylene. The second step is to produce a variety of organic chemical raw materials (about 200 kinds) and synthetic materials (plastics, synthetic fibers, and synthetic rubbers) with basic chemical raw materials. Spacecraft as large as space, as small as toothbrushes, are all closely related to petrochemicals. It can be said that petrochemical products are indispensable to everything in our daily life of "clothing, food, shelter, and transportation".

The fast-developing electronics industry and many high-tech industries have put forward new requirements for petrochemical products, especially fine chemical products produced with petrochemical products as raw materials, which is a huge boost to the development of the petrochemical industry.

The products or primary products processed with natural gas as raw materials mainly include synthetic ammonia, methanol, formaldehyde, ethylene, synthesis gas or hydrogen, acetylene, methyl chloride, carbon disulfide, hydrocyanic acid, carbon black, etc. Natural gas is also the best raw material for the manufacture of nitrogen fertilizer, which has the characteristics of low investment, low cost and low pollution.

summary

The downstream smart factories of oil and gas have begun to take shape. As the upstream oil and gas business is a traditional industrial industry, smart transformation is by no means an overnight effort. It is necessary to focus on smart transformation from the perspective of corporate development strategy and comprehensively promote the construction of smart oil and gas fields. Tupu software is based on partial refresh, batch aggregation, image caching, minimizing DOM elements, etc. It pursues the ultimate performance from the bottom of the design, and the components can withstand tens of thousands or even 100,000 levels of data. Help the oil and gas industry to break through the limits of application and realize smart and green development.

Use information fusion, cloud computing, fuzzy recognition and other technologies to achieve regional collaboration and data sharing, and through the analysis and processing of massive information and data, to achieve objective, essential and comprehensive cognition and judgment, so as to achieve the realization of oil and gas fields. Visual and measurable intelligent management and control. By connecting the dots and forming a faceted approach, we will break the unfavorable situation of each unit and each professional department establishing their own "information islands", and establish a scientific and effective intelligent oil and gas field information sharing mechanism.

Provide a brand-new management method for oil and gas field exploration and development, oil and gas production, operation management, and mining area services. Through the application of new methods, the level of ubiquity, visualization, and intelligence in all aspects will be improved, and ultimately promote the green and environmental protection of oil fields. Continuous development.

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。