Preface

With the acceleration of urban construction and the rapid growth of urban population, urban waste has become a heavy burden for development. According to incomplete statistics, my country produces nearly 150 million tons of municipal waste every year. How to deal with municipal waste has become one of the focuses of today's society. Waste incineration power generation can achieve the goal of pollution-free, reduction and recycling of waste at the fastest speed, and thus has been vigorously promoted. Before the "Twelfth Five-Year Plan", various places began to try waste incineration power generation. After the "Thirteenth Five-Year Plan", the waste incineration power generation project has developed rapidly in my country.

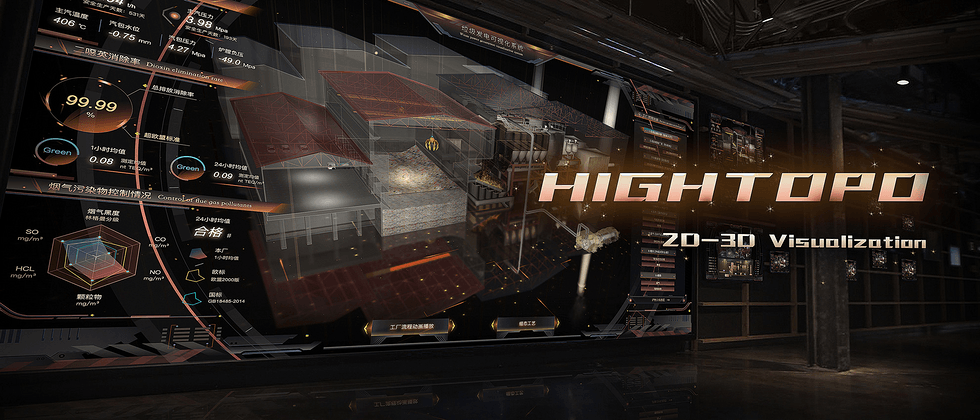

Hightopo takes waste incineration power generation as the research object, and relies on the self-developed HT for Web product to visually demonstrate its equipment process. Simulate the smoke and dust emission of the waste incineration power station, as well as the treatment technology, technological process, environmental conditions and machine failures. Visually display the execution progress of waste incineration, the operation status of equipment, the control status of flue gas pollutants, etc., and realize the visual management and application of production data of waste power stations.

effect display

An operation condition information management system based on visualization technology. In this case, a 3D model is constructed for waste-to-energy equipment and powertrain, and the 2D panel is linked to the 3D scene to help the operation and management personnel monitor the detection parameters in real time in the form of a chart, and use the 2D configuration to display the process visualization animation. Effects help clarify how things work. The factory process at each stage can be drilled down and switched to the 3D scene according to the specified command to meet the business needs of different managers.

On the left panel of HT, the control of flue gas pollutants, the elimination rate of dioxins, and key indicators of safe production are displayed in a loop.

System Analysis

Waste-to-energy process flow

HT uses the 2D configuration diagram to popularize the working principle of waste-to-energy generation, and managers can more intuitively see the working status and detection information of each system, including the fermentation time of the waste bin, the negative pressure of the waste bin, the residence time temperature of the flue gas furnace, DCS Furnace temperature, steam turbine temperature, etc., click "Configuration Process" in the scene to drill down and switch. Data visualization flowcharts of different dimensions meet the business demands of different managers and operators.

Garbage acceptance and feed visualization

Integrating the vehicle positioning display terminal, vehicle positioning and remote communication system, the status and information of garbage transport vehicles can be visually displayed through the 2D panel in the scene. In order to reasonably arrange garbage transportation vehicles to avoid the inconvenience caused by information lag.

Accurate and timely information about the Garbage Pool and grappling hook is obtained through GIS, garbage pool capacity, delivery volume, garbage pool opening time and different algorithms, digital twin garbage reception and feeding process, 2D panel display stock, negative Pressure, fermentation time, landfill seepage time, grapple operating status, working mode and load bearing. Help managers solve some problems in the feeding process, including whether the setting of garbage grabbing and dumping positions is reasonable, and whether the design and planning of waste-to-energy generation is sustainable.

Waste Incineration Visualization

After the garbage enters the incinerator, it is fully burned at high temperature. By combining the temperature measurement system, the system counts the furnace temperature, boiler feed water temperature, flue gas temperature and steam temperature in the incinerator, and monitors the operation status of the slag treatment system and the fly ash treatment system. Ensure that the fuel combustion energy in the furnace meets the needs of the boiler, maintain the safe and economical operation of the boiler, and maintain the stable operation of the incineration system.

Flue gas treatment visualization

The flue gas purification system is a system that combines the three steps of a semi-dry reaction tower, an activated carbon quantitative device, and a bag filter. HT performs virtual simulation of the flue gas generated by waste incineration, flue gas treatment system, and discharge into the atmosphere through the chimney after purification, and simulates the flue gas purification process in the scene. The flue gas passes through the waste heat boiler to release heat and then enters the spray absorption reaction tower.

The 2D panel updates the waste heat boiler steam pressure, steam temperature, feed water temperature, boiler blowdown rate, steam evaporation, and body resistance in real time.

Click the "semi-dry reaction tower" button on the right side of the flue gas, and you can clearly view the three-dimensional model of the semi-dry neutralization reaction tower, dry lime silo, activated carbon silo, as well as the operation and maintenance conditions and main parameters in the silo.

The bag-type dust collector captures the dust in the exhaust gas from the purification device, and the treated flue gas meets the requirements of environmental protection indicators, and is sent to the chimney by the induced draft fan for discharge, finally realizing the recycling of waste treatment.

Steam Turbine Visualization

The heat energy generated by the complete combustion of the waste incineration system is converted into steam by the waste heat boiler, and then converted into electricity by the steam turbine generator, thus completing a series of energy conversions. Combined with the 5G communication system, the system supports visual analysis of boiler combustion data in all aspects. The external structure and working state of the generator are presented through the 3D model; the steam flow, motor revolutions, power generation, and motor temperature are displayed on the 2D panel and automatically played.

Slag Sorting Process Demonstration

Slag is an indispensable product in the process of domestic waste incineration for power generation, and belongs to general solid waste. The sorted slag can be mixed with asphalt or cement to pave the ground and obtain good long-term use effect. HT supports the slag sorting process scene built by 2D lightweight model. Combined with the principle of slag sorting, the silo, sorting method, sorting process, etc. are presented in the form of logical diagrams, helping managers to review the operation context and saving slag processing cost, and effectively improve the utilization of resources.

Realized value

Improve technical process standards and reduce emissions harmful substances1623306b21eeef

After the garbage is incinerated, harmful substances will be produced, and these harmful substances need to be treated centrally. Combined with the actual operating environment of waste incineration power generation system and flue gas treatment system, the background system updates relevant technical parameters in a timely manner, adjusts the application status of various key technologies, improves process standards, and ensures the effective development of waste incineration power generation.

Improve system policies and improve operation management level

The automated and intelligent monitoring system established by HT improves the online detection of pollutant emissions such as dioxins and heavy metals, and tests the waste gas emission standards for waste incineration power generation. Managers can access the monitoring scene at any time by opening a browser through a PC, PAD or smartphone, avoiding falsification of air pollution emission data and ensuring the physical and mental health of surrounding residents. Promote the development of automatic, intelligent, intelligent and networked waste incineration power generation.

Summary

Under the background of carbon peaking and carbon neutrality, exploring the green value of waste incineration power generation industry has become the focus of development. Exploring and establishing a market mechanism that converts the social and environmental benefits of waste incineration power generation into green value is an important driving force for activating its high-quality development. Faced with the complex production process and process, Hightopo relies on its strong R&D support to build a visual solution for waste incineration, breaking through technical barriers, improving the level of operation and management, and speeding up to adapt to the new green and low-carbon situation. The management of incineration power generation provides valuable thinking and reference.

For more industry application examples, please refer to the case link of Tupu Software's official website: https://www.hightopo.com/demos/index.html

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。