foreword

Smart mine is a complex system that brings together multi-disciplinary, multi-theme, and multi-dimensional spatial information. It is the digital management, intelligent analysis, and visualization of all kinds of static and dynamic information involved in the engineering activities of mining mineral resources on the surface and underground of the mine. Display, so as to reduce costs and increase efficiency, and maximize the interests of enterprises.

Geological data is the basis and premise of 3D geological modeling, as well as the basis for mine resource assessment and mining design in actual projects, and one of the foundations of smart mines. Geological data are generally obtained in the form of engineering drilling. Through drilling, the basic lithological information and sampling analysis data can be obtained, so as to obtain detailed formation information, such as formation age, formation name, formation thickness, rock name, lithology description, bottom. Boundary depth, etc.

Through drilling data and various geophysical methods, we can obtain multiple cross-sectional information of the strata in the mining area. According to the section information, use the interpolation algorithm (inverse distance interpolation IDW or Kriging interpolation) to obtain the stratigraphic 3D grid data of the entire mining area. Using the web visualization engine of Tupu software, the grid data is presented to the web side, the spatial expansion of the geological intuitive display method is strengthened, the hidden geological information content is mined, and the data application value is improved.

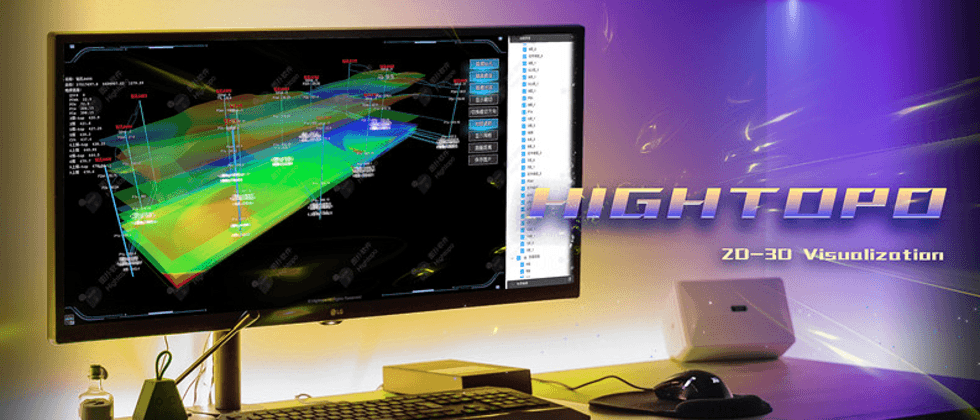

HT independently developed by Tupu Software is a web front-end 2D and 3D graphical interface development framework based on HTML5 standard technology. Provides a library of API components from the SDK to industry icons and 3D model resource libraries. Multi-dimensional visualization effects can be built, allowing users to have more choices for visualization scenarios.

Service-Terminal

Profile data and 3D mesh

Profile data is derived from borehole counts and exploration data. Profile data needs to be continuously revised as mining progresses.

A three-dimensional mesh is generated by an interpolation algorithm algorithm. The entire process is automated using algorithms. The administrator only needs to upload the mining data in the specified format to trigger the grid generation algorithm, and the system automatically regenerates the grid.

Manually Corrected Data

The front end of the system provides model editing functions, allowing users to modify models and upload modification information. The modification information is stored in the manual correction database of the server.

When the front-end model is displayed, the 3D mesh data and manual correction data will be automatically loaded to present the corrected model.

client

The front-end display contains the raw input data: borehole information and profile information. It is convenient for users to analyze whether the generated 3D mesh data is reasonable.

3D model and 2D data linkage

When the user clicks on the 3D model, the page automatically connects to the corresponding tree node, which is convenient for the user to quickly find information. Similarly, when the user clicks on a 2D tree node, the page automatically connects to the corresponding 3D model.

Drilling information display

The borehole information can be seen at an overview on the left, and the user can also intuitively see the location of the specific formation in the 3D scene. Users can cut the 3D stratum in any direction, observe the changes of the stratum, and save the picture of the cut plane.

Profile data display

model crop

Grid display and ranging function

Model editing

Front-end users can edit 3D models. The user can adjust the size of the edited area and the way the model is deformed. Adjust the shape of the model by dragging the control points with the mouse. At this time, the user can also modify the deformation curve, and the 3D model changes synchronously in real time. The front end uploads the modification information of the model to the server and saves it to the manual correction database.

The deformation curve is a Bezier curve. The Tupu SDK engine has built-in support for drawing Bezier curves, finding intersections and other geometric operations. The powerful and flexible 3D engine allows users to easily realize the rendering and editing functions of 3D models. Users don't need to care about tedious and complicated WebGL operations, they can focus on the business layer of smart coal mines, save development costs and speed up the development process.

System difficulties

The 3D mesh information is generated by an interpolation algorithm on the server side. The denser grid information contains more details, and the model is less distorted than the section information, but the amount of data generated is large, which puts pressure on network transmission and front-end display.

The relatively sparse grid data volume is small, the loading speed is fast, and the web page display is smooth. However, the detailed information is insufficient, and the regional model and the cropping plane with severe stratigraphic changes have large errors.

In order to meet various display requirements of the front-end page, the server side adopts a pyramid data structure to generate 3D grid information of multiple resolutions according to different grid spacings. The front end requests the corresponding grid information according to the displayed resolution requirements and the displayed area. Hide the part that is beyond the screen or not visible.

5G empowers mine intelligence

In the era of digital economy, the construction and implementation of future mines are constantly changing. With the support of new ICT technologies such as AI technology, intelligent exploration, Internet of Things, visualization, etc., the traditional mining industry has accelerated its development in the direction of green, safe, intelligent and efficient.

5G is one of the core technologies for digital transformation. Henan Yuexin signed a 5G technology cooperation agreement with Huawei, applying 5G technology to the field of unmanned mines for the first time. 5G continuously promotes the interconnection of all things, gradually realizes unmanned mining, maximizes mine production efficiency, and solves the problems of high risk factor, high labor intensity, and harsh operating environment in traditional manual operations in open-pit coal mines.

Open-pit mine visualization solution

The open-pit mine is to strip off the floating soil and surrounding rock covering the upper part of the ore body and its surroundings, transport the waste rock to the dump, and directly extract the ore from the open ore body.

The revolutionary changes brought by the extensive application of modern technology to the traditional mining industry not only make the mining employees feel the earth-shaking changes, but also make everyone have new and greater expectations for the further construction of intelligent mining areas.

Tupu software HT enhances the implementation and application of WebGL-based 3D GIS technology in mining, water conservancy, chemical industry and other fields. On the basis of traditional modeling, it introduces an aerial photography oblique photography 3D modeling solution to solve problems such as chemical parks and mines. The scene area is large, and the traditional 3dsmax maya and other tools have a huge workload for manual real scene modeling. Through drone aerial photography and post-processing data, the original 3D model of HT is seamlessly integrated, which solves the integration of macro and micro. ization needs.

There are two main ways to acquire 3D scene data in open pit mines: one is through aerial photography modeling; the other is through artificial modeling.

Aerial photography modeling, also known as 3D oblique photography, is a GIS technology that has developed rapidly in recent years. Using aircraft or drones equipped with multiple sensors, the ground objects are photographed and collected from five directions, front, rear, left, right, and vertical, so as to quickly and efficiently obtain data information that truly reflects the ground conditions. Through a series of professional processing operations such as correction, adjustment, and multi-view image matching, the 3D model is finally obtained.

Manual modeling is mainly based on a certain range of scene graphs or CAD drawings combined with real photos to manually model the ground situation.

Tupu independently developed HTML5-based 2D and 3D graphics rendering engines, providing BIM, GIS, VR, XR, MR, 23D visualization web-side solutions, and also widely used in smart cities, park buildings, twin factories, intelligent manufacturing, Digital twin and data visualization projects in various industrial Internet industries such as smart water and smart energy.

In the field of mining, Tupu Software and its partners have successfully implemented the 3D visualization integrated operation and maintenance system of Zijin Mining's global multinational mine sites:

The visualization of Tupu software breaks the phenomenon of enterprise data silos, continuously promotes the digitalization of industries in all directions and multiple dimensions, realizes the interconnection of information, and carries out the full coverage of digitalization transformation. Help the industry to achieve safe, green, efficient and intelligent development, empower the construction of zero-carbon mines and the realization of dual-carbon goals, and ultimately build a modernization where man and nature coexist in harmony.

For more industry application examples, please refer to the case link on the official website of Tupu Software:

https://www.hightopo.com/demos/index.html

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。