foreword

With the advancement and development of visualization technology, the configuration page displayed by the traditional reclaimed water plant configuration system has gradually been unable to meet the current diversified display methods. As a result, the system is relatively weak in monitoring and analysis of sludge treatment and disposal and production and operation costs. It is urgent to display diversified information application results and various information resources and support convenient access to diversified terminals.

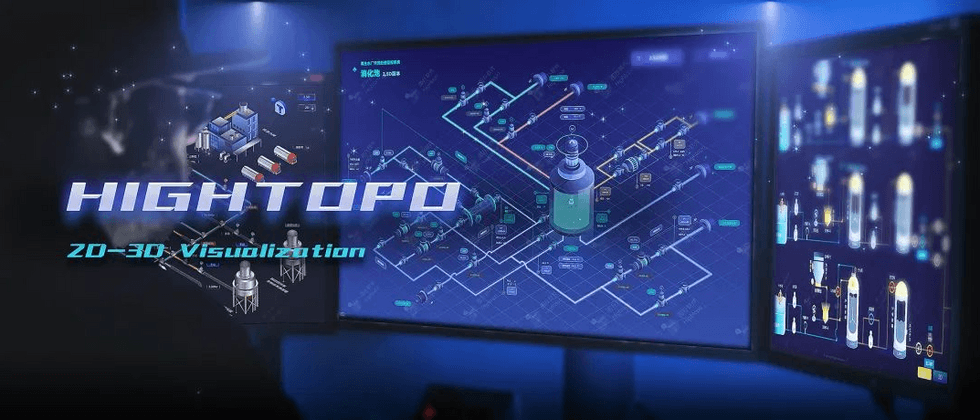

The HT visualization technology of Tupu software adopts B/S architecture. By reconstructing the traditional two-dimensional water plant configuration diagram, it can connect the measurement point data to realize Web-based cross-platform multi-terminal access, whether it is opened by PC, PAD or smartphone. Browser, you can access the monitoring scene at any time. And supports integration into B/S side, seamless integration with other mainstream front-end frameworks such as Angular, React and Vue, breaking the limitations of previous user control scenarios in the control room, and enabling new configurations to use 2D/ 2.5D and other different forms to achieve diversified display.

Show results

This case introduces the 2D/2.5D visual design of the main process flow in the reclaimed water plant area, according to the business unit "digesting tank system", "flocculant system", "external sludge receiving system" for classification design, combined with The real-time data monitored after access to the measuring point can visually present the operation status of the process flow and process equipment.

digester system

What is the digestion of sludge? Anaerobic digestion is a process in which most of the solid organic matter in sludge is hydrolyzed, liquefied and finally decomposed by anaerobic microorganisms through hydrolysis, acidification, methane production and other processes. Methanogens eventually convert the carbon in the sludge organic matter into methane and release it from the sludge to stabilize the sludge.

In the visualization interface of Tupu software HT, the digester system is divided into two modes: 2D and 2.5D. In the 2D configuration mode, the digester, heat exchanger, flame arrester, main valve, multi-stage pipeline, etc. are mainly displayed. The digester monitors the production data by binding the liquid level, temperature, mixer current, shaft temperature and frequency in the tank. In addition, commands can be issued through the interface to achieve the purpose of remotely controlling the mode switching of the mixer; various valves in the overall configuration system can display data such as flow, flow rate, pressure and other data through the back-end transmission interface, and at the same time, manual switching can be performed. and automatic mode; PH value, water temperature, real-time flow rate and other data can also be monitored on key pipelines.

2D effect display

2.5D effect display

The 2.5D configuration interface adopts a relatively sci-fi style design, and displays the technological process and operation monitoring of the entire digester system through three-dimensional effects.

Flocculant preparation system

The method of solid-liquid separation by flocculation and sedimentation is one of the important separation methods in the current water treatment technology. When using aqueous polymer as a flocculant to treat industrial wastewater, domestic wastewater, industrial water supply, circulating cooling water, and civil water, it has the advantages of promoting The water quality is clarified, the filtration speed of the settled sludge is accelerated, the amount of sludge is reduced, and the filter cake is easy to dispose of.

In the new 2D configuration interface, through the HT engine technology of Tupu software, the development of smooth dynamic effect of configuration primitives is realized. This system shows the flow of 3 flocculant preparation production lines, using a fixed panel to display the real-time data of the preparation system such as liquid concentration, preparation times, stirring mode setting, system operation status, etc.; as well as key equipment preparation tanks, storage tank liquids bits, main valve data, etc.

2D effect display

2.5D effect display

The 2.5D effect has a more three-dimensional sense of space and achieves a spatial distribution effect that is consistent with the real scene.

External sludge receiving system

Sludge treatment and disposal should follow the principle of source reduction and whole-process control, strengthen the source control of toxic and harmful substances, and select appropriate sewage and sludge treatment processes according to the final safe disposal requirements of sludge and sludge characteristics.

The goal of sludge treatment and disposal is to achieve the reduction, stabilization and harmlessness of sludge; to encourage the recovery and utilization of energy and resources in sludge. Adhere to the realization of sludge treatment, disposal and comprehensive utilization under the premise of safety, environmental protection and economy, so as to achieve the purpose of energy saving, emission reduction and the development of circular economy.

The external sludge receiving system mainly shows the sludge storage, dehydration, and outbound transportation processes. The key node data includes the silo material level, hopper material level, the liquid level of the dilution mud unit, the liquid level of the dilution water unit, and the flow and pressure on the key pipelines. data; the main valve supports switching between manual and automatic modes.

2D effect display

2.5D effect display

Using the 2.5D configuration interface, the process distribution of the entire process and the process direction of each sub-process can be seen more intuitively.

Realize value

The process monitoring system of the reclaimed water plant embodied in the Tupu case above is only the tip of the iceberg of the whole system. The ultimate purpose of realizing a new and complete 2D/2.5D configuration process for water plants is to satisfy the decision-making of the group and the management personnel to implement multi-dimensional comprehensive applications such as operation, management, command, and scheduling for their business units, helping enterprises to land quickly. The whole process of water distribution, water purification, water delivery, and refined management of processes and facilities can efficiently avoid secondary pollution problems in urban water supply, and establish a credible visual decision-making platform for the group's production, operation, management and scheduling.

Tupu software also supports the use of 3D lightweight modeling to build a water affairs supervision platform, relying on GIS, BIM, video fusion and other technologies to jointly build a digital backplane, to achieve a comprehensive perception of the operation status of the drainage and supply network, and to strengthen the management of the whole life cycle of water affairs construction .

Summarize

During the "14th Five-Year Plan" period, the plan clarified that it is necessary to build a smart water conservancy system, and take the basin as a unit to improve the ability of water forecasting and intelligent dispatching. In this context, all parts of the country are in full swing to promote the construction of smart water affairs, with the purpose of reducing leakage rate and improving management efficiency, accelerating the realization of digitalization of water affairs information, automation of equipment control, and intelligent development of decision-making analysis.

Compared with traditional configuration software such as InTouch/IFix/WinCC, Tupu's web-based platform is more suitable for the general trend of C/S to B/S transformation. The multi-element rich visualization components and fast data binding methods are available. for rapid creation and deployment. Provide 2D, 2.5D, 3D clear and beautiful visualization service modes for various industrial scenarios.

Compared with the traditional interface, Tupu satisfies the modern, high-performance, cross-platform (desktop Mouse / mobile Touch / virtual reality VR) graphic display effect and interactive experience of the Industrial Internet of Things. It is an advantage that the C-side platform does not have to easily open the mobile terminal and terminal demand interface, and realize the one-finger rotation, two-finger zooming, and three-finger translation operations of touch screen devices, so there is no need to worry about different cross-platform interaction modes. At the same time, it also supports display combined with VR/AR, allowing users to immerse themselves in a virtual environment for experience, especially for large-scale scenes such as factories, workshops, and production lines.

The advanced configuration interface of Tupu software is very suitable for the interface presentation of real-time monitoring system. It has been widely used in telecommunications network topology and equipment management for many years, as well as industrial production, urban parks, rail transit, electric power, warehousing and logistics, chemical metallurgy, etc. In the field of industrial automation (HMI/SCADA/MMI), the business covers data display, situational awareness, scientific decision-making and other life-cycle monitoring. Focusing on the bottleneck links of many industrial chains, guided by the integration and application of digital technology and various fields, promoting cross-border innovation in the industry, and striving to become a leading brand in the field of localization and graphic configuration in the field of industrial Internet in my country.

For more industry application examples, please refer to the case link on the official website of Tupu Software: https://www.hightopo.com/demos/index.html

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。