Before reading the article, you can think about what kind of definition 2.5D design belongs to?

2.5D is to present a three-dimensional effect through two-dimensional elements. In fact, there is no such name as 2.5D in foreign countries. The standard statement is Isometric style, which translates to isometric design, which is called 2.5D in China.

The academic name of 2.5D is axonometric illustration or axonometric illustration. The meaning of axonometric illustration, as the name suggests, is a single-sided projection diagram, which can simultaneously reflect the shape of the three coordinate planes of the object on one projection plane, and is close to people. Visual habits, image, lifelike, full of three-dimensional sense.

That is to say, the three sides of the object are drawn in a two-dimensional production method, which is full of three-dimensional effect. However, axonometric illustrations need to find a perspective surface, which requires a high degree of spatial imagination of the designer. The difficulty and time cost of the production will be higher than the three-dimensional workload depending on the complexity of the graphics.

foreword

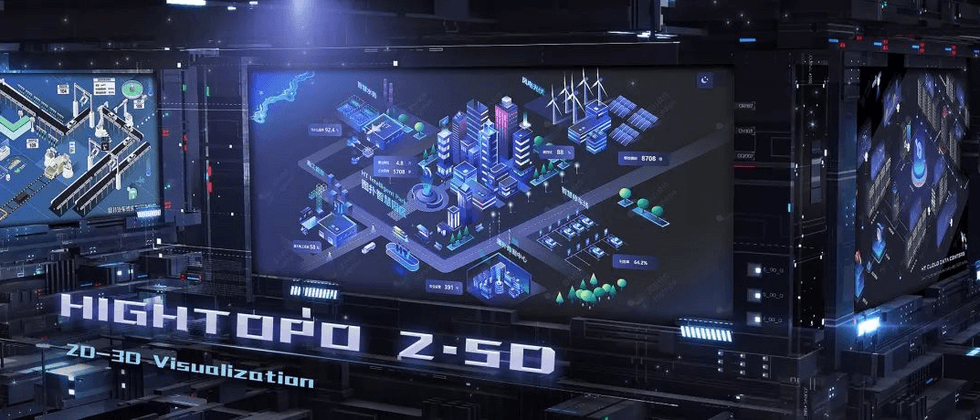

Tupu software combines 2.5D graphics technology with data visualization, which can help solve the problems of high application development cost, long cycle and poor experience in various fields such as smart industry, smart park, smart computer room, and smart energy.

Using the Web configuration on the HT products independently developed by Hightopo, combined with the 2.5D lightweight design form, transparently monitor the multi-service operation processes in the fields of smart parks, smart computer rooms, smart SMT production lines, and smart car production lines. The rich graphic components and interface design of Tupu make the boring and tedious data graphical and scene-based, and make a clear comparison of the data of each chart more intuitively.

System analysis

Smart Park

As a microcosm of the city in the region, the park gathers various resource elements such as industry, manpower, innovation, and functions.

Based on the new generation of information and communication technology, Tupu software integrates building, energy efficiency, parking lot, construction, and energy in the park management and control interface, and horizontally opens up various sub-business systems to realize the integration of park control, perception, monitoring, and analysis.

The use of data-driven forms allows new configurations to be displayed in various forms such as 2.5D, and to achieve spatial distribution effects consistent with real scenes. It can be set to switch between day and night scenes at will, and the overall design is based on a realistic style.

In view of the current integrated operation form of "source, network, load and storage" implemented in the park, this case takes data as the core production factor, and monitors the real-time data of power generation, consumption, and power storage after accessing the measuring point, and provides process visualization animation effects and The chart data is loaded into the fusion form and displayed visually. Integrate the location distribution, operation status, and environmental situation of facilities and equipment in the park, carbon emissions, computer room operation, and implement centralized dynamic monitoring and deployment. You can click to view multiple distribution characteristics under the same data indicator, forming a real-time sharing of park resource space. , Balance management, linkage control.

Based on multiple dimensions such as type, area, and quality, a threshold alarm trigger mechanism is constructed for the operation status of various events in the park, such as energy consumption load, construction progress, engine room dynamic environment, parking space statistics, and water quality, so that the system can actively identify safety risks. Avoid security risks.

Web-based cross-platform multi-terminal access can be realized by docking the measurement point data, and cross-platform browsing is supported. Any mobile terminal can easily open the browser to access the management interface, and use a variety of control devices to centrally and remotely control the display content. advantages that are not available.

data center

The visual management method of the data center is to collect and summarize the complex information of various management systems in a virtual environment, and choose a way that conforms to human vision to fully display the overall structure of the data center. It satisfies the end-to-end IT visibility of operation and maintenance personnel, clearly and quickly grasps the location and asset information of various devices, and accurately examines the overall situation of the data center.

Topu software is equipped with intelligent sensors to connect the power, assets, capacity, dynamic ring, access control and other information to be monitored in the area, so as to help decision makers observe various objects as much as possible. In the new 2.5D configuration interface, through the powerful engine technology of Tupu software HT, the development of smooth dynamic effect of configuration primitives is realized. Display any required asset object data in the interface in a list and refresh it dynamically, such as: computer room power load, UPS, equipment model, CPU load, temperature and humidity, etc.

Equipped with pipeline visualization, it helps operation and maintenance personnel to effectively sort out the dense electrical pipelines and network lines in the data center, easily control the link direction and pipeline distribution of the data center, and improve the efficiency of troubleshooting and repairing pipeline faults.

Re-integrate the existing operation and maintenance system and service model, and gather various types of massive and complex system information here, improve resource utilization, shorten fault response time, and create standardized, refined, and intelligent business operation processes for users.

SMT production line

As a highly automated workshop, SMT workshop can use advanced technologies such as intelligent equipment, FIRD, network, etc., with Tupu visualization technology, so that the traditional information manufacturing industry can realize unified management and operation of data, and enable the industry to develop towards intelligence and green.

Tupu software uses lightweight modeling to build a 2.5D SMT process monitoring and management visualization solution, and quickly files the basic information of each production line. Each production line in the overall configuration system can be transmitted through the back-end interface. Use the chart component to feed back the running data monitored in real time. The 2.5D configuration interface can more three-dimensionally see the process distribution of the entire process and the process trend of each sub-process.

According to the operation requirements of the factory area, the operation results can be constructed based on user data, and multi-dimensional data panel content can be built on demand, such as: OEE (Comprehensive Equipment Efficiency), time utilization rate, performance utilization rate, output completion, straight-through rate, defect rate, etc. .

There is an early warning alarm analysis function. If the device data exceeds the critical value, the user will be reminded to pay attention to the device in the interface in time. Users can issue commands through the interface to achieve the purpose of remotely controlling the start and stop of the device mode, thereby improving work efficiency and reducing operating costs.

Tupu software visualization combines B/S architecture with model light weight, which relieves the user's pressure on purchasing high-performance hardware to a certain extent.

Automobile production line

The automobile manufacturing industry is a typical discrete manufacturing. Compared with ordinary production lines, the automobile production process is more complicated and cumbersome.

Tupu Software's 2.5D visualization solution for automobile production lines, applies the 2D configuration and 3D configuration effects of various cartoons to the production process such as stamping-welding-painting-final assembly, restores the animation scene and integrates it into the large screen. Make the whole process of automobile production online, transparent, visible, controllable and traceable.

Equipped with various types of sensors to collect the production data of the internal equipment in the welding workshop, and use the HT visualization component of the Tupu software to build a visual kanban for the production line, allowing users to monitor the team work, employee efficiency and production line utilization, stamping process, and line stoppage during the process. / The time of dumping the car is clear at a glance.

Based on the HT engine technology of Tupu software, it is based on the Internet of Things, takes big data as the center, takes each production line as the carrier, takes stamping, welding, painting, and final assembly as the core smelting process coordination as the goal, and develops big data processing. Technology, machine learning, machine vision and automatic control and other technologies are used as means to realize intelligent collaborative manufacturing with the best overall cost and the lowest energy efficiency.

The accurate, concise and intuitive quantitative management form of Tupu software helps users to gain a comprehensive and rapid insight into the spatiotemporal characteristics and changing laws behind complex data, which changes the previous fragmented, scattered and general management methods.

Summarize

Hightopo also supports the use of 3D lightweight modeling to build monitoring scenarios. Combined with professional analysis and prediction models, the scenarios of parks, computer rooms, SMT, and automobile production lines can be refined and presented to achieve multi-angle and diversified parameters for demand scenarios. analyze. Promote the online work of the whole process, release a lot of repetitive work, empower employees to collaborate efficiently, and improve the overall organizational efficiency. At the same time, it has the characteristics of light weight, high efficiency, ease of use and cross-platform, and truly achieves the seamless integration of 2D and 3D. Designers and programmers unify the collaborative development mode of tools, achieve high-speed iteration of product development, and quickly turn ideas into 2D, Final interface results in 2.5D and 3D.

Tupu software visualization supports editor's custom style, layout and menu toolbar. 2D and 3D scenes can be nested, superimposed, rotated and scaled on the editor, highly componentized and seamlessly integrated, carrying more than 100,000 2D, 3D and UI table tree general component primitives, to meet the massive Internet of Things Device and data scenario requirements.

Tupu software not only works well in traditional configuration applications, but also shows its capabilities in emerging 3D configuration industry applications. The configuration pages presented meet the diversified display methods at the current stage, and have accumulated many in many fields. Industry system implementation solutions to create a rich 2D configuration and 3D configuration. It is convenient for users to get started quickly, helps the rapid upgrading and transformation of the manufacturing process, further improves the production and management capabilities, and realizes more exquisite industrial monitoring visualization systems.

Compared with the traditional configuration software InTouch/IFix/WinCC, the web-based platform of Tupu software is more suitable for the general trend of C/S to B/S transformation, supports fast data binding and multi-element rich visualization components, available for rapid creation and deployment. It has become a leading brand in the field of data visualization graphic configuration, telecommunication network topology, and industrial automation (HMI/SCADA/MMI).

For more industry application examples, please refer to the case link on the official website of Tupu Software: https://www.hightopo.com/demos/index.html

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。