foreword

As of 2021, 127 countries around the world have made a commitment to "carbon neutrality", and low-carbon energy transition and carbon neutrality have become common global strategic goals. According to authoritative agency forecasts, by 2050, renewable energy power generation will account for more than 75% of the world's total power generation. As a typical representative of clean energy, wind power will meet 35% of electricity demand and contribute 27% of carbon emission reduction to climate goals.

Xiang Haitu is strong and strives to be the first. Compared with onshore, offshore wind power is more complex, comparable to the moon landing project. Intelligence is one of the breakthroughs in the development of offshore wind power. When the weather, power, operating status of equipment, and user-side usage can be well predicted, the utilization rate of energy and the economy of electricity consumption will have a qualitative leap.

Show results

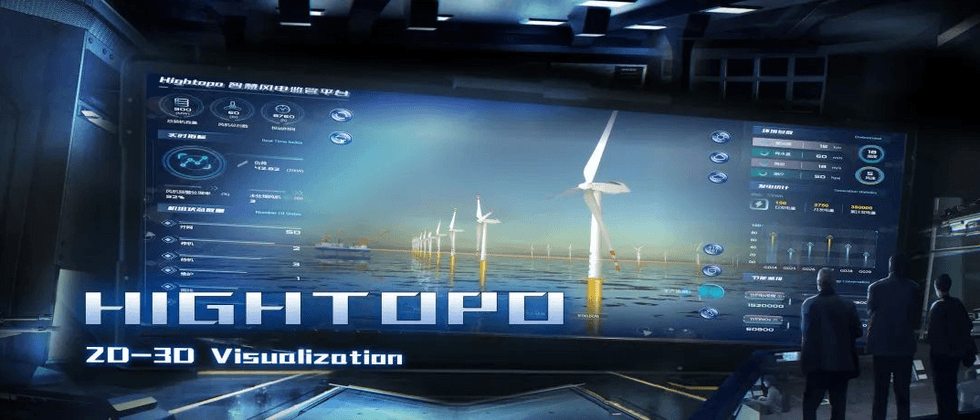

Based on the independent research and development engine HT for Web of Tupu software, it seamlessly integrates 2D and 3D technologies to realize interactive Web 3D offshore wind power scenarios.

Panorama

The scene can conduct roaming inspections of wind farms according to free viewing angles and fixed routes.

The system also sets 3 different weather modes, with day and night scenes, you can switch to view the scene changes at different times. And display the information of wind turbine equipment and centralized control center in the path, presenting the overall appearance of the wind farm to users.

sea effect

The scene uses an algorithm to draw the custom material into a unique mimetic water surface effect and a dynamic sky ball effect. According to the water surface texture and water surface fluctuation information, the water surface effect is simulated. Realize the switching of water surface texture and fluctuation information; adjustment of water surface texture direction, texture and flow direction; water surface color adjustment; adjustment of light reflection intensity; adjustment of illumination angle and color; adjustment of water surface wave size. The visual fidelity of the scene display is improved, and the three-dimensional sense and the sense of hierarchy are enhanced.

System analysis

Production monitoring

Tupu software HT restores the wind turbine model, layout, work and status of the overall three-dimensional wind farm 1:1 according to the actual scene. Users can choose the viewing angle of the tour by themselves, and view the scene effects and details by zooming in, zooming out and panning the scene. The environmental parameters, real-time power generation indicators, energy saving and emission reduction information and other data are connected to the HT 2D panel of the Tupu software, which is convenient for the operation and maintenance personnel to effectively control the operation of the entire base.

Environmental parameter visualization

The marine environment is relatively harsh, especially under extreme weather conditions such as typhoons, online monitoring of environmental parameters is particularly important. The HT engine of the Tupu software displays the marine environment of the offshore wind power operation area in a unified manner by connecting the monitoring result data of the sensors and the high-speed transmission medium, including the monitoring of wave elements, wind speed, visibility, precipitation, sea waves, tides, temperature, humidity and other items. Achieve all-weather and multi-environment early warning and prevention capabilities.

Power Generation Statistics Visualization

Offshore wind power is a power generation method that converts offshore wind energy into electrical energy, and is a "beautiful business card" of clean energy and green energy. Through intelligent management methods, it is conducive to the improvement of offshore wind power generation.

Integrate modern information technologies such as big data, mobile internet, artificial intelligence, and advanced communication technologies to realize energy efficiency integration of wind farms. The 2D panel displays the daily power generation, monthly power generation, and total cumulative power generation of the wind turbines, and displays the power generation and power generation differences of the wind turbines at different locations through a bar chart. Assist the staff to analyze the reasons for the loss of electricity and evaluate the inefficient fans. According to the maintenance experience, a fault diagnosis system for wind turbines can be formed, and based on data mining technology, intelligent diagnosis and processing guidance of wind turbines can be realized.

Energy saving and emission reduction visualization

The energy-saving and emission-reduction module is highly integrated on the basis of other systems to realize energy-saving information sharing and intelligent management, online display of the amount of standard coal and NOX saved and the total amount of CO2 and SO2 reduced, effectively improving the efficiency and effectiveness of offshore wind power utilization and management . To support the clean and low-carbon transformation of energy and contribute to the realization of the "double carbon" goal.

Real-time indicators and unit status visualization

Tupu software HT is based on the digital modeling of wind farms, multi-dimensional real-time monitoring of wind turbine operating status, load parameters, and preventive maintenance. Display the real-time indicators of fan working information and the number of unit status through a 2D and 3D seamless integration panel, including load, fan early warning processing rate, untreated fans, etc. And the number of grid-connected, shutdown, standby, maintenance, offline, and faulty fans. Relying on the data center to build remote fault early warning and diagnosis capabilities, realize intelligent operation and maintenance services, and improve efficiency.

safety management

Safety management focuses on the operation supervision of fans, submarine cables and electronic fences. Combined with the all-round access of new energy equipment, comprehensive data analysis and equipment early warning functions are realized. Strengthen risk identification and prevention and control capabilities, ensure the safety of business personnel, and scientifically promote the progress of offshore wind power projects.

Fan early warning statistics visualization

Through the one-to-one supervision of the main equipment "fan" of the wind farm, it can connect to various types of fault alarm information interfaces of different equipment components to meet the needs of early warning analysis under various conditions.

In addition, Hightopo has set up an information module for early warning feedback and early warning elimination on the system, including problems such as abnormal fan speed, high cabin control temperature, and no feedback from hydraulic pumps. Through early warning analysis, the changing trend of the fan can be found in advance, the operating parameters can be adjusted, and the maintenance treatment can be arranged as soon as possible; by eliminating defects in advance, avoiding the expansion of small problems and causing failures, providing effective methods and data analysis support for the development of preventive maintenance work, so as to achieve The preventive maintenance in the true sense promotes the specialized division of labor in the operation module.

The non-grid-connected fans in the scene are marked with a predetermined color, and combined with the current fan speed to drive the fan rotation animation in the grid-connected state. It can quickly identify equipment abnormalities, find faulty equipment in time, quickly locate the fault point, and check the fan fault information in time by clicking on the faulty fan, so as to carry out targeted fault diagnosis and treatment, and eliminate hidden dangers in time.

Visualization of submarine cable warning statistics

Submarine cables (collection lines) are the key components of power transmission in offshore wind farms. However, due to changes in transmission power, complex subsea environment, ocean temperature changes during the day and night, seasonal temperature differences, as well as fishing, shipping and subsea activities, submarine cables are prone to problems. Accidents such as overtemperature and anchor damage occurred, resulting in great losses.

Tupu software draws and renders the distribution trend of submarine cables by connecting with the new technology of optical fiber distributed sensing. The 3D scene vividly shows the distribution and operation status of the submarine cable. Double-click the submarine cable with the left mouse button to pop up the corresponding information on the submarine cable such as temperature, current carrying capacity, strain force, etc. Combined with the visualization data of the Tupu software HT, the average parameter is displayed. The value and maximum value information is convenient for managers to infer the real state in the context of the data, so as to carry out effective supervision.

The alarm type can be freely set according to the actual situation, such as abnormal temperature, environmental damage, etc., and the abnormal status can be refreshed and displayed in real time. And through the corresponding fan to alarm and locate the abnormal submarine cable, judge whether the cable is damaged or whether the surrounding environment has changed, so as to ensure the safe operation of the submarine cable.

Visualization of abnormal statistics of electronic fence

The electronic fence of wind power water area and the equipped early warning system provide a visual solution for the safety monitoring, early warning and maintenance of wind power water area. By docking with the shipping system, relevant information such as construction vessels, fishing vessels, and illegally invaded vessels can be obtained. Combined with the invasion time and departure time, the ship's position (longitude and latitude) can be located in real time and historical trajectories can be drawn to improve monitoring and management efficiency.

Use Tupu software to visualize the rich design elements to visually display the complex data of the electronic fence. When the ship approaches or invades the electronic fence, specific alarm information will appear in time, reminding the supervision and management personnel to quickly make the next decision, so as to play a role in Protect the role of related equipment and facilities in the electronic fence.

Video surveillance early warning visualization

Traditional video surveillance is integrated into its own video surveillance system, and the cameras are distinguished by text naming, which can easily lead to a series of problems: video dispersion, isolation, incomplete viewing angle, unclear location of hardware, etc. . The 3D visualization system built by HT supports access to the corresponding camera video image according to the actual point of the on-site camera to achieve scene restoration.

The camera position distribution on the booster station can be seen at a glance through the 3D scene. Support scene interaction to retrieve the corresponding surveillance video to meet the monitoring needs of operation and maintenance personnel for real-time situational awareness of the scene, historical data retrospective comparison, and emergency response plans.

construction management

There are a lot of high-altitude operations in the construction stage of offshore wind farms, with many potential safety hazards and great danger, especially for the lifting of piles, transportation, and personnel high-altitude operations. . The specific functions of the system cover the entire life cycle of offshore wind farm construction, operation and maintenance, including construction safety management and control, construction quality, wind turbines, and integrated monitoring of construction progress. It aims to play a greater role in the dimensions of safety, cost reduction, and efficiency enhancement.

Construction progress and plan visualization

The construction progress was disclosed using the 3D visualization technology of Tupu software. Based on the HT graphics engine, and for the real scene, the real construction scenes such as wind turbines and submarine cables are deeply integrated with the digital platform through satellite images and CAD drawings. By connecting the construction progress data interface, the real-time status display of the whole process of fan construction in the scene can be realized, and the overall construction process can be restored according to the time axis. Form the visualization of the overall construction progress and the progress of fans and submarine cables.

And supplemented by the construction plan, including time, construction objects, number of ships and number of people. It is convenient to analyze various indicators in the construction process, and business personnel can coordinate and coordinate all parties through the platform without going to the site.

Construction quality and safety visualization

Combine HT visualization and construction management system, and access offshore wind power construction management data to the visualization platform. The 2D panel updates the key information of construction quality and construction safety in real time, including the number of problems found, rectification status, problems that have not been rectified, and the person in charge. It makes the supervision of wind farms more intuitive and the control more accurate.

Visualization of construction details

In order to fully complete the hoisting and pile driving construction, it is necessary not only to do a good job in the preliminary planning, but also to pay attention to the control and review of the construction technical plan. The HT engine of the Tupu software monitors and tracks the construction indicators of the fan and booster station in real time, and realizes the optimization and improvement of the hoisting and transportation scheme for many times; checking the fan foundation piling, tower hoisting, blade hoisting, waiting to be put into operation and boosting Various technical support data, such as the construction of the bottom of the station, to be put into operation, and the hoisting of the superstructure, have accumulated experience for the subsequent foundation construction and contributed to the vigorous development of the offshore wind power field in the deep water area.

Booster station information visualization

The offshore wind farm booster station consists of two parts, namely the offshore booster station and the onshore switching station. The layout of the onshore switch station is the same as that of the onshore substation. The offshore booster station operates in an unattended mode, and its management and control are monitored in real time by the onshore centralized control center through a remote method.

The HT 3D visualization booster station section of Tupu software restores the equipment in the scene by high-precision modeling. Click the corresponding icon to quickly switch and locate the internal structure of the booster station, helping to realize the unattended operation of the booster station.

Support the monitoring and measurement of the voltage and current of each grounding transformer substation, grounding transformer incoming line and submarine cable in the offshore booster station and onshore switching station, so as to analyze the abnormal operation before the equipment fails to ensure the equipment. Safe and stable operation.

Intelligent inspection

The daily maintenance of the booster station requires inspection personnel to check the equipment, which is not only inefficient, but also very dangerous. Tupu software is based on GIS indoor spatial positioning calibration, integrates the indoor positioning coordinates of the remote inspection robot, and realizes an intelligent inspection system with 1:1 scene restoration, which more visually shows the current inspection status of the robot.

Realize the display of the current state data of the patrol robot, real-time monitoring information of the patrol camera is transmitted back in real time, and displayed on the visualization platform through the HT engine. The operation and maintenance personnel and duty personnel can view the application conditions of each main transformation room through mobile phones or mobile terminals. When the high-voltage equipment is grounded, avoid personal electric shock injury, improve detection accuracy and efficiency, and reduce inspection blind spots.

Popular science tips

Compared with the existing open DC switch and DC GIS equipment, the miniaturized GIS equipment applied to the offshore platform is small in size, and the GIS room occupies a small area, which can reduce the space occupied by the switchgear by more than 70%, and can make the offshore converter platform volume. decrease by about 10%.

Summarize

Under the "dual carbon" goal, the next five to ten years will be a critical period for my country's energy transformation and development. As one of the main forces, wind power has a major task. By combining industrial data and big data, Tupu software innovates the operation and maintenance mode and management method, which helps the preventive maintenance of wind turbines and the auxiliary decision-making of wind farms, improves the efficiency of wind power operation and maintenance, reduces the cost of wind power operation and maintenance, and increases the power generation. In the future, Tupu Software will continue to give full play to the resource advantages of the industrial Internet platform, implement the green commitment, broaden the development path, and contribute to the realization of the national "dual carbon" goal.

For more industry application examples, please refer to the case link on the official website of Tupu Software: https://www.hightopo.com/demos/index.html

**粗体** _斜体_ [链接](http://example.com) `代码` - 列表 > 引用。你还可以使用@来通知其他用户。